Increasing technological advances and rapid technological development have brought great convenience to the work. The use of special equipment, high speed for the enterprise to create profits, reduce costs and improve efficiency. Understand the actual scope of application of the equipment, according to the actual situation to buy the applicable equipment, the maximum value of the equipment. As the name suggests, special equipment for packaging products, manual packaging products with low efficiency, and product loss, especially now it is difficult to recruit workers, it is difficult to recruit workers to stay, which largely affects the productivity of enterprises. Automatic packaging machine is good for enterprises to solve the actual problem, and can save costs, improve efficiency, with the amount of equipment easy to operate.

Automatic packaging machine for a wide range of uses, packaging machines used in a number of industry sectors, common agricultural products, daily necessities, food, spices, pharmaceuticals, hardware, fertilizers and many other areas, in other words, any product packaging, to meet the product requirements of customers, improve the efficiency of product packaging, work efficiently, save costs and increase economic benefits for enterprises, the equipment plays a role that can not be ignored.

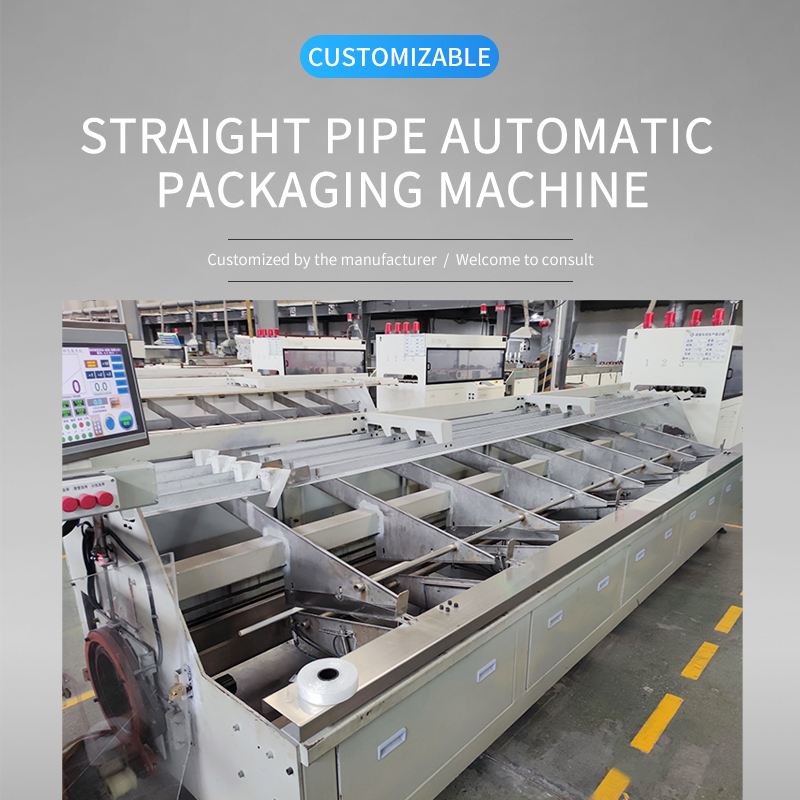

Advantages of straight pipe automatic packaging machine

1.high efficiency

The traditional manual packaging production efficiency is relatively slow and easy to lose material, with automatic packaging machine instead of manual packaging can efficiently complete the feeding, measuring, bagging, printing the date, the product output all the production process. This mechanized assembly line production measurement accuracy, efficiency, saving materials while also reducing labor costs.

2.reduce labor intensity

Automatic packaging machine instead of manual packaging so that workers are freed from the heavy work. First of all, like some small products manual packaging is physically demanding and not easy to pack; secondly, some products produced during the production process will produce dust, radioactive, irritating toxic hazards to humans. The production of the machine can effectively solve these problems.

3.energy saving and environmental protection

Generally good service automatic packaging machine have automatic detection of this function, so for those products that are not packaged in the machine can be intelligent automatic screening again for repackaging, improving the rate of compliance while not wasting materials, in reducing losses while also facilitating maintenance and operation, to a large extent, reducing production costs.

4.Safety and hygiene

Manual packaging due to manual participation is difficult to avoid human contact with the production of products, which may contaminate the product resulting in production quality is difficult to ensure. Automatic packaging machine from feeding to finished products throughout the automated production without human involvement, this packaging line to reduce bacterial contamination of the packaging chain, providing a good guarantee for the enterprise.

Jintuo Intelligent Equipment (Chengdu) Co., Ltd. was established on July 31, 2020, and its registered office is located at No. 1, 1st Floor, Building 2, No. 1236, North Section of Hongye Avenue, Chongzhou Economic Development Zone, Chengdu. The business scope includes manufacturing of intelligent mechanical and electrical equipment and accessories; manufacturing of intelligent warehousing and logistics equipment and accessories; manufacturing of machine vision equipment and accessories; The new science and technology developed by express transportation has successively obtained at least 4 patented technologies in the areas of unpacking manipulator, plate stacking, rapid lifting and turning of pipes, etc., which greatly improves the speed and accuracy of transportation and saves time and labor costs.

Wang Qing

314916188@qq.com