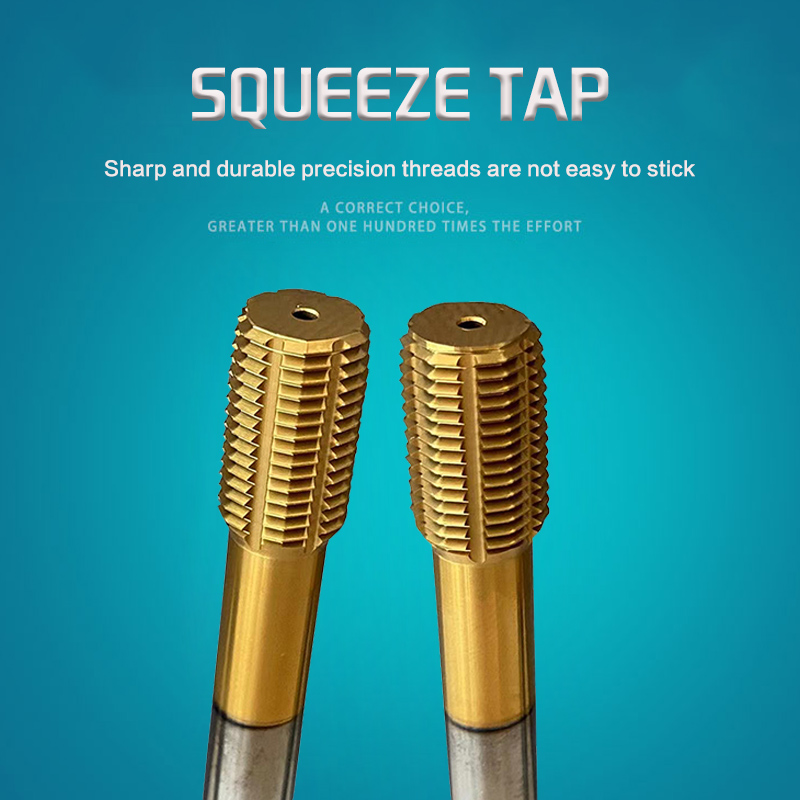

Extrusion tap features:

1. Extrusion tap has higher strength than cutting tap, it has the advantages of not easy to wear, long service life, low breaking rate and high production efficiency and cutting;

2. The extrusion tap is threaded through the metal flow, so it has the characteristics of high strength, smooth surface and easy to ensure the processing size;

3. Extrusion tap has self-guiding, can be used in the general work wire equipment, but because the extrusion tap processing needs greater torque than the cutting processing, so the tapping equipment torque requirements are larger, extrusion tap torque is generally 1 ~ 1.5 times of the cutting tap;

4. With the extruded tap extrusion thread surface finish is high, the metal fiber of the thread is not broken, and the formation of a layer of cold and hard layer on the surface, can improve the strength and wear resistance of the thread. It fundamentally solves the chip removal difficulties of tapping, because there is no chip, more conducive to thread assembly. Widely used in electronics, plastics industry.

Extrusion tap is the use of metal plastic deformation principle and processing internal thread of a new type of thread tool, extrusion tap extrusion internal thread is chip free processing technology, especially suitable for low strength, plastic good copper alloy and aluminum alloy, can also be used for stainless steel and low carbon steel hardness, plastic material tapping, long life, specifications.

It is a tool for machining internal threads, with grooves along the axial direction. Also called a tap. Tap according to its shape is divided into straight groove tap, spiral groove tap and screw tip tap. The straight groove tap is easy to process, the precision is slightly lower, and the output is larger. Generally used for ordinary lathe, drilling machine and tapping machine thread processing, cutting speed is slow. Spiral groove tap is used for drilling blind holes in cnc machining center. It has fast processing speed, high precision, good chip removal and good neutrality. The front part of the screw tip tap has a capacity cutting groove for the through hole processing. Most of the taps supplied by tool factory are coated taps, which have a great improvement in service life and cutting performance compared with uncoated taps.

Founded in 2012, sichuan guangjuda technology co., ltd. Is located in aba industrial park, huaizhou new town, jintang county, covering an area of 30,000 square meters. The company takes the production of high precision cutting tools as its own responsibility, set research and development, production, sales as one.

Ten years grinding a sword, we always focus on the tool industry, has introduced advanced processing and testing equipment at home and abroad, the production of tap, drill, milling cutter, reamer tool mainly serves in aerospace, automotive, military, machinery and other industries.

We are not only an excellent supplier of cutting tools, but also cooperate with a number of the world's excellent cutting tools brand, agent their brands, set the strengths of each. General contracting service is a major feature of our company, with mature experience in general contracting management, technical team and operation team. Has a total contract of more than 10 listed companies tool business, from the process optimization, program formulation, tool production, field application guidance, tool management, participation in the whole process, to provide efficient, high quality service for customer service, for customer production escort, while saving the cost of customers, improve the competitiveness of customer products.

The pursuit of quality, continuous innovation, heart service, we will always adhere to the direction.

Mei Liu

466147170@qq.com